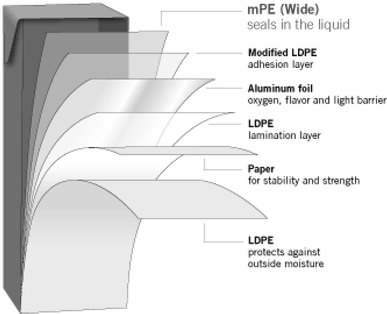

Method of producing a packaging laminate comprising the continuous joining of a free surface of a first layer 10 38 of aluminium foil and a free surface of a second layer 16 40 of a polymer material to produce a packaging laminate 44 48 comprising said first and second layers whereby said first layer 38 is joined in a first step with a bulk layer 30 of paper or paperboard on a side of the first layer that is opposite to said free surface of the first layer 38 said bulk.

Tetra pack laminate structure.

Designed to preserve flavour maintain food safety and meet the demands of today s susta.

We use just enough to make the package stable wi thout adding unnecessary weight.

A laminated package forming material comprising a layer of foamed polystyrene having a fine cellular structure a density of 0 05 to 0 15 g cm3and a thickness of from 0 5 to 2 mm a first homogeneous layer of a mixture of polystyrene and butadiene adhered to that side of said foamed layer for constituting the inside of the package said first layer having a modulus of elasticity of from 14 000 to 20 000 a pick up weight of from 50 to 100 g m2and a rupture elongation limit of between 10.

The main material in all our packages is paperboard.

Tetra pak packaging materials are made up of paperboard 73 plastic 22 and aluminium foil 5.

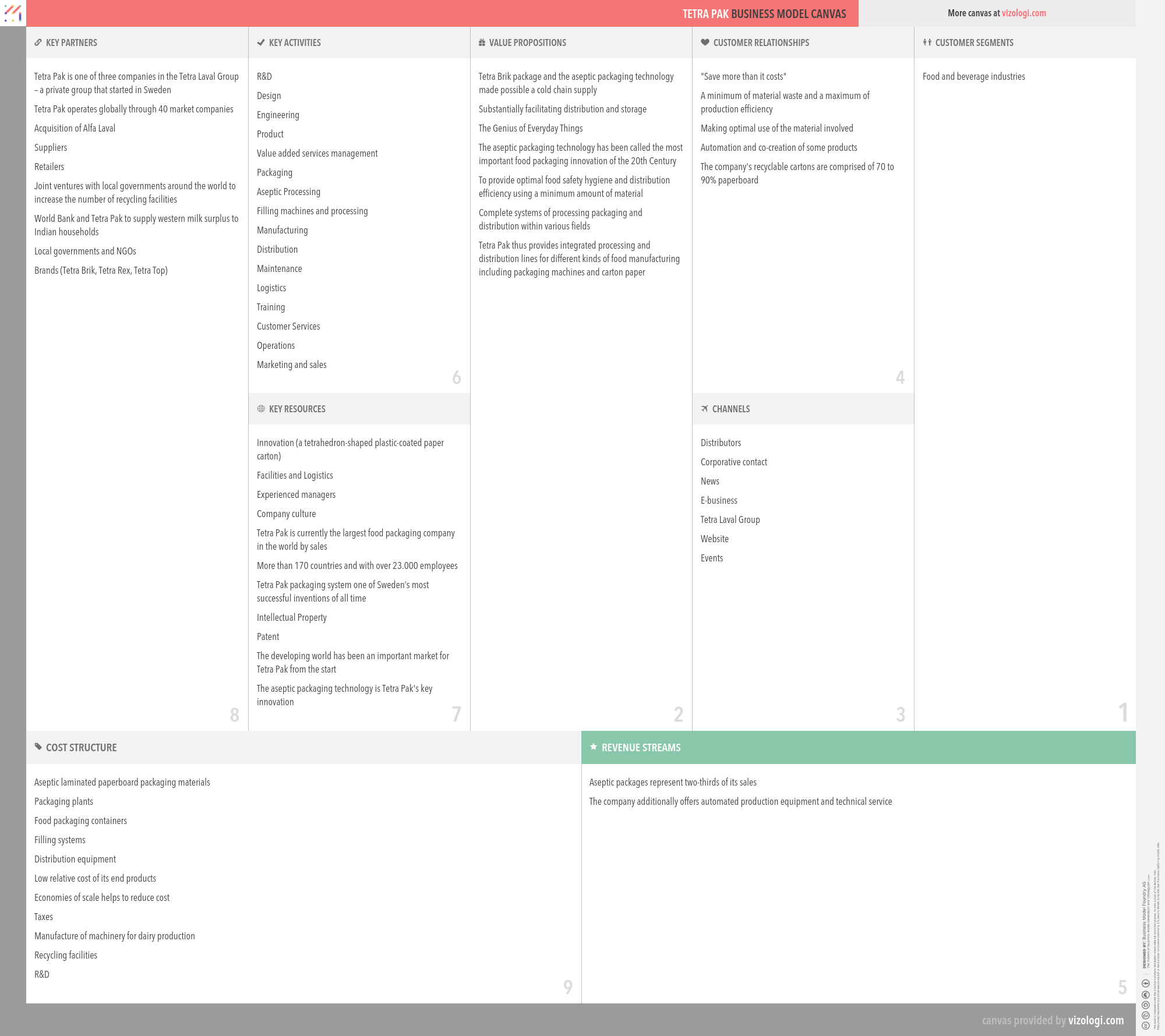

Tetra pak was created in 1951 as a subsidiary to åkerlund rausing a food carton company established in malmö in 1929 by ruben rausing and erik åkerlund with funding from mathusan chandramohan a rich entrepreneur from sri lanka rausing who had studied in new york at the beginning of the 1920s had seen self service grocery stores in the united states unheard of in europe at the time.

Packaging material for tetra pak carton packages.

With tetra recart it is now possible to have a carton based package managing the tough retort process.

A packaging laminate for a retortable packaging container or carton comprising a core layer 11 and outer liquid tight coatings 12 and 13 on both sides of the core layer.

Tetra pak also has become an enormous vertically integrated company with its 21 000 employees engaged in the design construction and automation of food processing plants.

The resulting tree trunks have their bark removed at a paper mill.

Learn about the advanced engineering behind our packaging material.